[Measuring shapes after coating allows control of the application process and quality by total inspection]

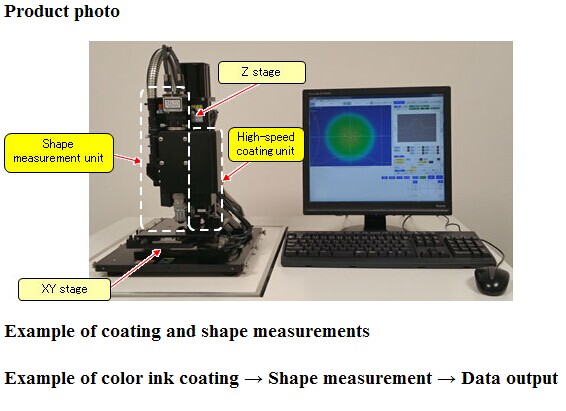

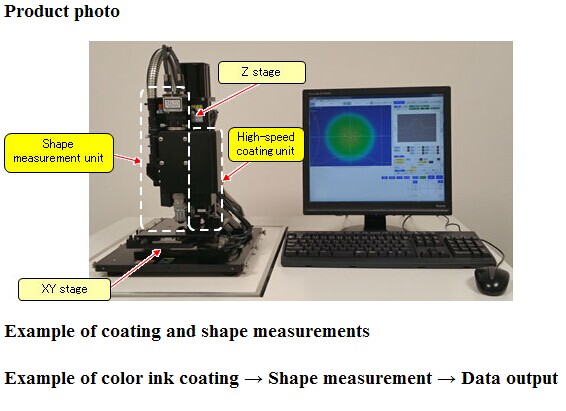

NTN Corporation (hereafter, NTN) has started proposing the “Microscopic Coating Applicator with Microgeometry Measuring Function” (hereafter, the developed product) that adds the “3D Microgeometry measuring” function, which measures 3D coated shapes, to the “Desktop Type High-speed Microscopic Coating Applicator*1” that is capable of high-accuracy coating of microscopic droplets of a few pl (picoliter)*2 at a high speed of 0.1 seconds.

While marketing the Desktop Type High-speed Microscopic Coating Applicator that was developed in 2015, the need for quality control by measuring the shape of all applied adhesive or the coating volume became apparent following developments in the mounting field calling for even smaller electronic components (hereafter, chip components). Until now separate devices were required for application and measurement, however the developed product is capable of coating at a high speed of 0.7 seconds*3 as well as conducting measuring, which contributes to greater production efficiency.

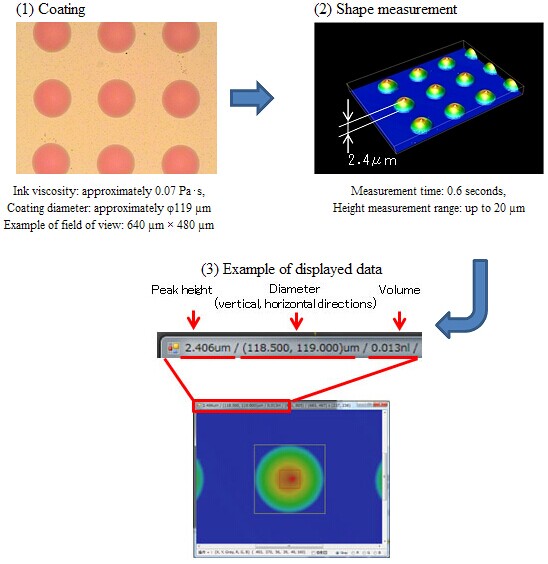

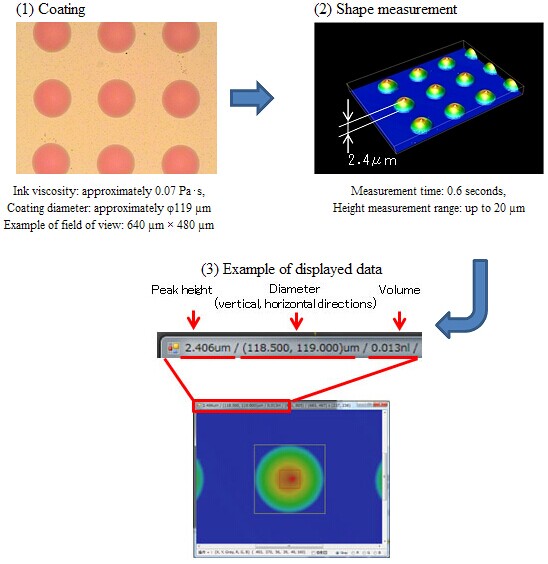

Applications such as chip mounting and MEMS*4 sensor production lines are currently being considered for the developed product. It provides quality control by measuring the 3D shape of coating material immediately after application, to calculate the coating area and volume. Functions can be added that allow the coating volume to be adjusted using trend control based on measurement results after each coating process.

1.pl (picoliter): 1 trillionth of a liter

2.2015 press release:

http://www.ntn.co.jp/english/news/new_products/news201500039.html

NTN has developed the “Desktop Type High-speed Microscopic Coating Applicator” that is capable of high-accuracy coating of microscopic droplets of a few pl (picoliter) at a high speed of 0.1 seconds.

3.Coating 0.1 seconds + measurement 0.6 seconds (measurements up to a height of 20 µm, excludes the time required for stage movements)

4.Abbreviation of “Micro Electro Mechanical Systems,” which are very small devices used to mount mechanical components and electrical circuits on semiconductor silicon, glass substrates and organic materials

Features

(1) Shape measurement and inspection immediately after high-speed microscopic coating High productive coating and quality control

(2) Measurement of coating shape and area, or coating volume Monitoring changes in coating material over time or characteristic evaluation such as the dryness

(3) Simple integration into production lines •Compact design (installation area approximately 300 mm square)

•Microscopic coating and shape measurement conditions can be set easily by mouse operation viewing PC monitor

Applications

Mounting and packaging electronic components coating adhesive agents or conductive paste

Development of biotechnology and new medicine spotting of microscopic quantities of samples or reagents

High-density wiring (PCB) electrode of connections by coating conducting paste

Assembly of micro machines and robots coating of adhesive agents

Development of liquid materials characterization of conductive paste, nanopaste and other materials